Finite Element Analysis

Finite Element Analysis in India | KHAAS Design & Engineering

At KHAAS Group, we offer specialized Finite Element Analysis (FEA) services that help engineering teams make smarter, safer, and more efficient design decisions. Whether you’re validating a pressure vessel, optimizing a mechanical component, or checking the structural integrity of complex assemblies — our FEA solutions provide deep insights into how your designs perform under real-world conditions.

Our experienced analysts use industry-leading FEA tools to deliver precise, reliable simulations that reduce development costs and eliminate failure risks early in the design process.

Why Choose FEA?

Reduce Physical Prototypes — Cut costs and lead time by simulating early.

Improve Design Quality — Identify stress concentrations and failure points.

Optimize Materials & Geometry — Achieve higher performance at lower cost.

Validate Compliance — Meet industry codes and safety standards.

Who We Serve

Our FEA services are trusted across a wide range of sectors, including:

Civil & Structural Engineering

Building & Infrastructure

Offshore & Marine Structures

Renewable Energy (Wind, Solar, Hydro)

Transportation (Rail, Automotive)

Aerospace & Defense

Industrial Equipment & Machinery

Our FEA Capabilities

We provide advanced simulation and analysis services tailored to your project needs, including:

-

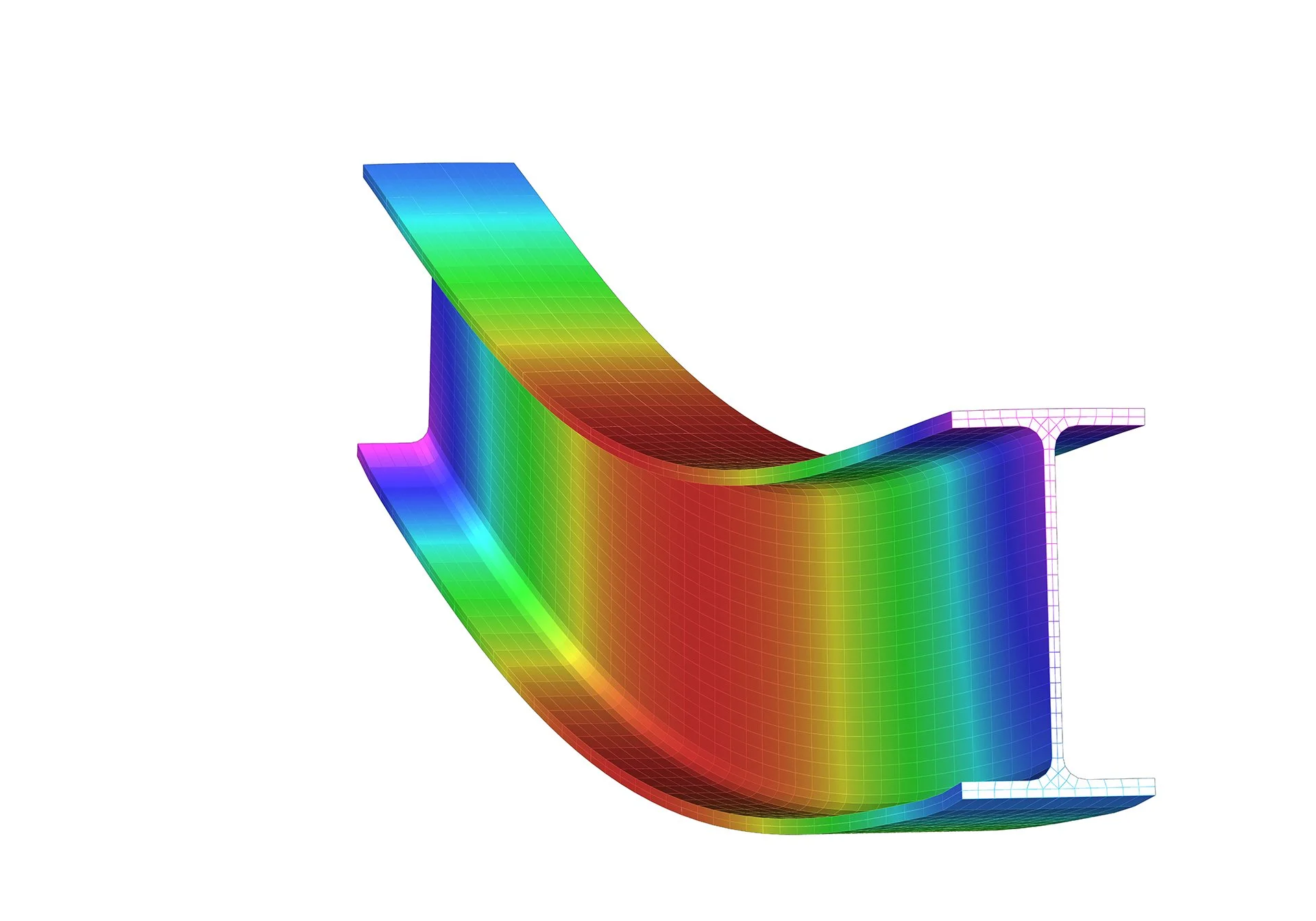

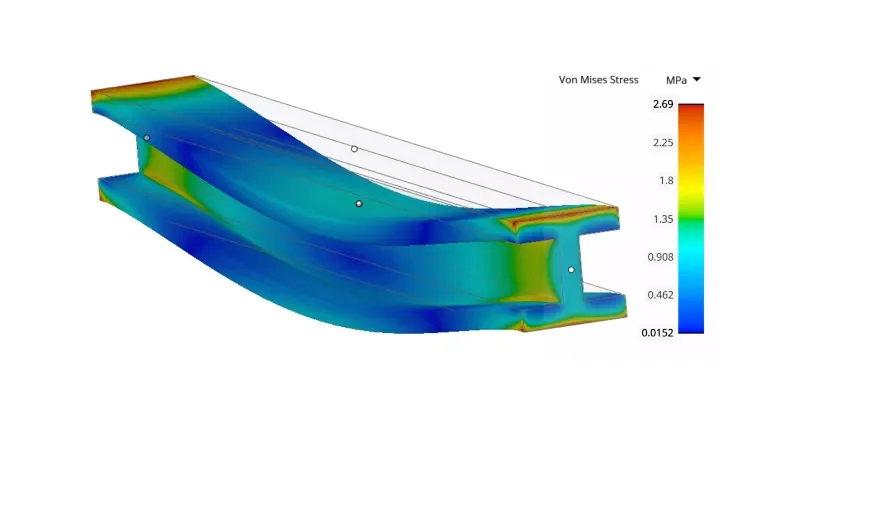

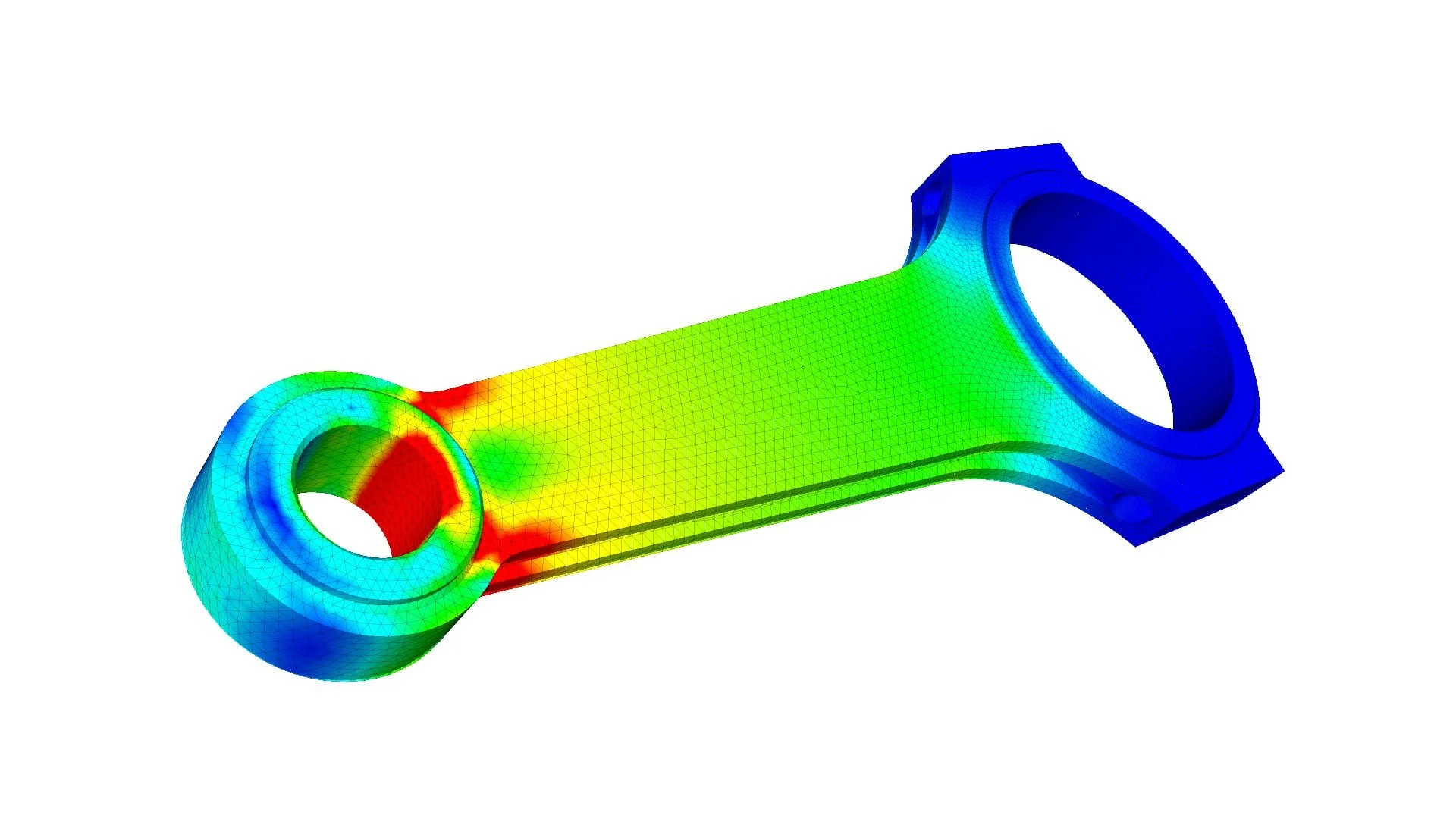

Evaluate how your structure performs under static loads, including material non-linearity, large deformations, and contact behavior.

-

Simulate time-dependent effects including vibration, seismic loading, impact events, and harmonic response.

-

Analyze how temperature variations impact structural integrity and material behavior.

-

Identify critical load conditions that may lead to sudden structural failure.

-

Predict lifespan and failure risks due to cyclic loading or material defects.

-

Specialized modeling for materials with directional properties such as CFRP, GFRP, or laminated assemblies.

Why Choose KHAAS?

Experienced Structural Engineers with deep domain knowledge

Certified FEA Analysts using validated modeling practices

Results You Can Trust – Peer-reviewed reports and full documentation

Optimization & Design Iteration Support to help improve performance and reduce costs

Collaborative Approach – We work closely with your team to align with your goals

Deliverables

Every FEA project includes:

3D Models and Simulation Setup

Mesh Convergence Studies

Visual Output: Stress/Strain/Displacement Contour Plots

Safety Factors and Critical Area Identification

Technical Report with Assumptions, Methodology & Recommendations

Ready to Start?

Whether you're validating a prototype, optimizing a complex structure, or troubleshooting a failure, our FEA services can help de-risk your project and accelerate design confidence.